Situation

Noggerath® Centre-Flo™ CF & Screening Wash Press NWP

Herdorf, Germany

The optimum machine solution for existing inlets to wastewater treatment plants. Mechanical pretreatment

The presentation of the technology of the newly developed Noggerath® band screen Centre-FloTM at the Hellertal wastewater association aroused interest to the extent that a trial was started at the Herdorf wastewater treatment plant some years ago. The aim of this trial was to test the suitability of the technology in the inlet area of the wastewater treatment plant as the first mechanical treatment stage. The installation of the Noggerath® Centre-FloTM band screen at the Herdorf wastewater treatment plant was the first trial model of its kind in Germany.

For this project, the newly developed Noggerath® Centre-FloTM band screen was equipped with screening elements with a honeycomb structure and 5 mm hexagonal perforations. This increases the free screening surface to 90%, enabling the customer's hydraulic requirements to be met in future. During the test phase, it was found that the separation performance of the Noggerath® Centre-FloTM band screen is significantly higher than that of the perforated screen installed at the wastewater treatment plant.

Solution

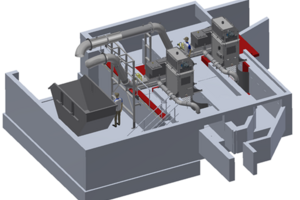

This convincing result was the decisive factor for the customer to implement the conversion of the screening plant based on this technology. A Noggerath® screenings washing press was also installed, this is the ideal complement to the Noggerath® Centre-FloTM band screen due to its compactness and high degree of dewatering. The entire fine screen system is also extremely space-saving and easy to install. In combination with a Noggerath® screenings wash press, with the unique, stable perforated plate bottom with brush-tipped spiral and the resulting fast dewatering with a high degree of dewatering. This installation is the perfect combination in wastewater screening for the future. Thanks to the fine screening, the smallest particles such as hair, paper and plastic particles being separated very reliably. The externally positioned spray bar ensures a high and targeted cleaning of the honeycomb screen elements.

It should be particularly emphasized that this machine technology can be used to create redundancy without having to carry out conversion work on the screen building, as the Noggerath® Centre-FloTM band screen has an integrated emergency overflow.

The customer's requirements could therefore be implemented in the existing screen building with a main channel and an emergency overflow channel (secondary channel) without any structural changes. This included complete redundancy of the machine technology - each channel can handle the entire wastewater volume. Furthermore, maintenance work can be carried out without operational downtime.

Advantages

Noggerath® band screen Centre-FloTM

- High retention rate of contaminants (doubling the screenings volume)

- High hydraulic capacity due to the use of honeycomb filter elements

- No transfer of dirty water to the clean water side

- External chainless drive, therefore no contamination on the drive elements and good accessibility for maintenance work

- Easy replacement of individual filter elements

- The machine can be easily lifted out of the sewer thanks to the bolted base plate on the channel

- The emergency bypass has become a fully-fledged second screen channel

Noggerath® screenings washing press NWP 300 / 1500

- Very high degree of dewatering

- Unique, stable perforated plate bottom

- low speed, therefore gentler and more intensive washing

Technical Data

Centre FloTM No. 1 in main channel and Centre-FloTM No. 2 in secondary channel

| Size | Centre-Flo™ 600-1050 |

| Flow rate max. | 420 l/s |

| Channel width | 1100 mm or 1200mm |

| Channel depth | 1400 mm |

| Shape of the screen opening | Hex Panel Honeycomb |

| Filter element opening | 5 mm |

Noggerath® screenings washing press NWP 300 / 1500

| Max. capacity (continuous operation) | 3.5 m³/h |

| Washing capacity (cycle operation) | 2.5 m³/h |

| Washing water consumption | 2(3/4") l/s (fresh or process water) |

| at water pressure | 4 bar |

| Dry matter content of the screenings | up to ~ 35 - 45% |

Features:

- Modular design (dewatering zone perforated screen / pressing zone perforated screen)

- Spiral with plastic brush

Special features Hopper:

- Connection for Centre-Flo™ alluvial channel

- With emergency overflow in front of the screen

- Level measurement with radar probe